Isahluko sokuqala

Isingeniso Somkhiqizo

Inqamula umqondo wokuklama wendabuko kanye nezindlela zokukhiqiza, futhi ihlanganisa izici zemakethe eziyisiyingi ezisikiwe zenqwaba, sakha umshini wethu wokuluka oyindilinga ngokuzimela.

Izicelo:

Ingubo, ukhaphethi, uboya bekhorali, inqwaba ephezulu, indwangu kaphayini, i-peacock cashmere, uboya be-PV, i-cashmere yotshani nazo zonke izinhlobo zempahla yezingubo.

Idatha yobuchwepheshe:

Imodeli: YF3012;YF3016;YF3020;YF3214;YF3218;YF3222;YF3418;YF3420;YF3422;YF3620;YF3622;YF3822;YF3824;YF3826;YF3828;YF4022;YF4026;YF4030;YF4428;YF4432

Ububanzi besilinda: 30-38inch

Isilinganiso senaliti: 14G-32G

Isiphakeli: 12F-32F

I-RPM: 1-23r/min

Amandla: 4kw, 5.5kw

Ukuphakama kwenqwaba: 4-25, 25-50mm

Isahluko sesibili

Ukukhipha kanye Nokufakwa

Ukulayishwa kozimele oyinhloko

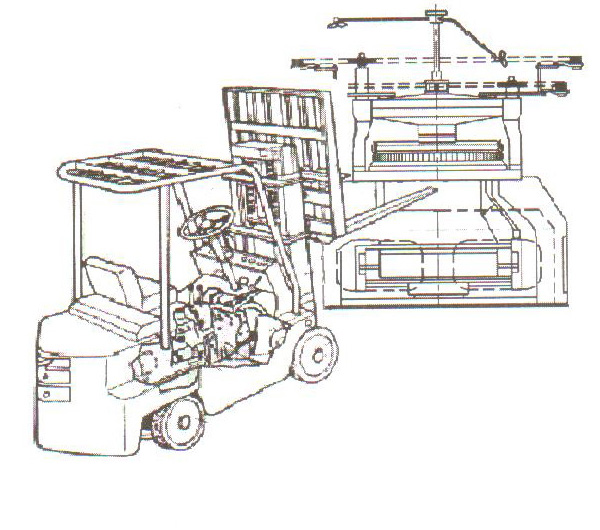

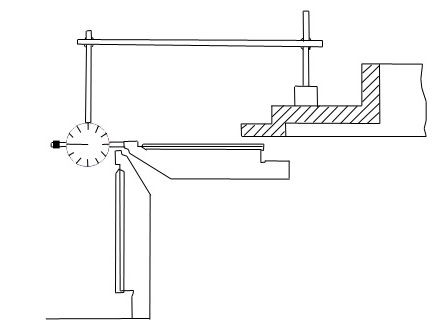

Sebenzisa iforklift engaphezu kwamathani angu-5 ukuze wehlise uhlaka, indlela eboniswe kumfanekiso 1-1, pl fundaimiyalelo ngezansi:

1.Ngaphambi kokuthulula, hambisa isistimu yokudlulisa ngesandla ukuze wenze isibuyisela emuva indwangu sihambisane nonyawo oluyinhloko (imvamisa, imishini ibilokhu ikulesi simo ngaphambi kokulethwa).

2.Layisha ingalo ye-forklift phakathi kwamapheya amabili ezinyawo kancane, bese uphakamisa uye phezulu usuka phansi (qaphela: vala isigxobo sokhuni phakathi kwengalo nomshini, ukugwema ukulimala ngenxa yokushelela komshini ngesikhathi uthulula)

3.Ngesikhathi uthulula, gcina umshini cishe u-30-50cm ngaphezu komhlaba, ungavunyelwe ukugijima emgwaqeni onamaqhuqhuva, ungavunyelwe ukuma noma ukunyakaza ngokuzumayo, futhi ukhanyise phezulu naphansi ngokucophelela.

4.Uma umshini ungazange ulethe embonini yekhasimende, sicela uqiniseke ukuthi ubeka endaweni eyomile nehlanzekile, ukuze ugweme ukuthinteka nge-dame nokugqwala, ukugwema ukusetshenziswa komshini okuvamile.

Indawo nokufakwa komshini:

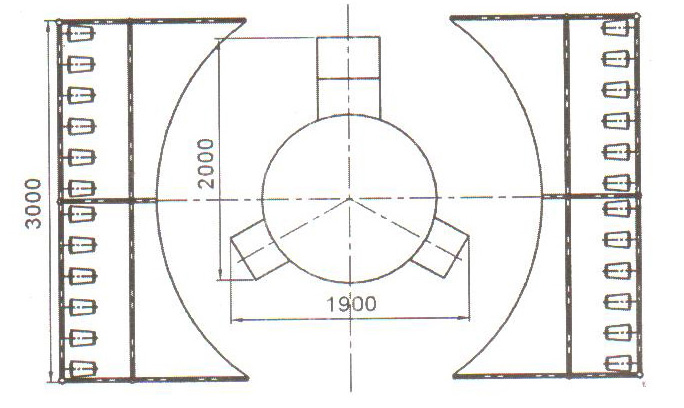

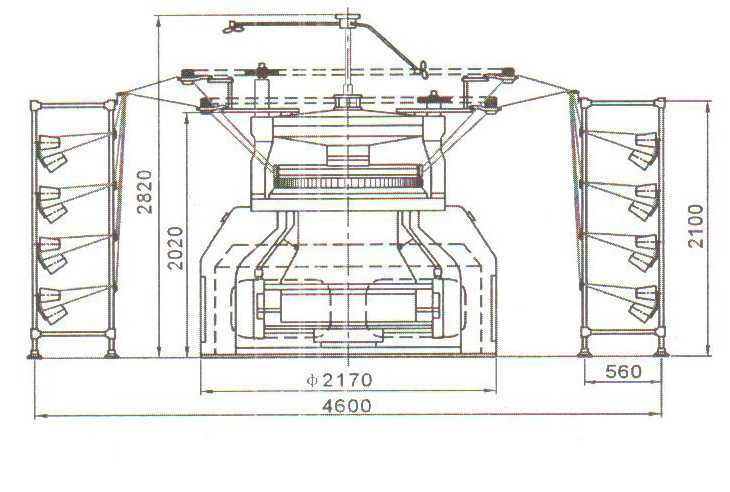

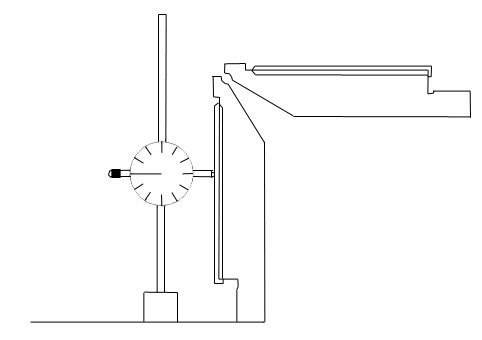

1.Ngaphambi kokulungisa indawo, linganisa indawo yohlaka kanye ne-creel ukuze uqinisekise indawo yokufaka, ngokuya ngosayizi kumfanekiso 1-2.

2.Ngemva kokulungisa indawo, sebenzisa i-gradient ukuze ulinganise indawo yomshini ngokucophelela (ingakwazi ukulungisa isikulufu sonyawo sezinyawo eziyinhloko kanye ne-vice, ukuze uqinisekise iphutha elingemuva lingabi ngaphezu kuka-5mm)

Indawo kanye nokuhlanganiswa kwe-creel

1.Qinisekisa isikhundla se-creel ngokusho kosayizi we-1-2.

2.Xhuma ikholomu ye-Cylindrical kanye ne-transom, bese usetha ifremu yecreel

3.Faka imicu ye-aluminium ewugqinsi emine ngemuva kwe-creel (ukufaka ithrekhi yeshubhu lentambo), kanti eminye emincane emine kufanele ifakwe ngaphambi kwe-creel(ukufaka idivayisi yokucindezela)

4.Ubude bemicu ye-aluminium yokuphakela intambo kufanele bube phezulu kune-aluminium yokucindezela, ngakho-ke lapho ukuniwa, ukuphakelwa kwentambo kuzoba bushelelezi, ngeke kuphuke kalula.

5.Faka idivayisi yokucindezela emigqeni ye-aluminium yangaphambili, faka ithrekhi yeshubhu lentambo ye-creel emigqeni ye-aluminium engemuva.Gcina ibanga elifanayo ukuze ugweme ukuphakelwa kwezintambo.

Inhlanganisela yentambo yokuthumela

1.Faka futhi ulungise ama-creel feeding creel namakholomu

2.Faka ifreyimu eyindilinga phezulu, idivayisi yokugcina intambo kanye nezintambo zokuphakela amandla zedivayisi yokumisa okuzenzakalelayo.

3.Faka ifreyimu eyisiyingi ephansi, idivayisi yokugcina intambo ephansi kanye nezintambo zokuphakela amandla zedivayisi yokumisa okuzenzakalelayo.

4.Faka ibhande lokudlulisela phezulu naphansi.

5.Faka umqoqi wothuli oluphezulu naphansi, naka ukulungisa ukuma kwefeni.

6.Lungisa ipuleti le-aluminium yentambo

7.Xhuma amandla edivayisi yokumisa okuzenzakalelayo.

Isahluko Sesithathu

Izinga Lobuchwepheshe Nokulungiswa Okuyisisekelo

Yonke imishini yethu yenziwa ngomjovo oqinile, ukulungisa kanye nomsebenzi Wokuthuma ngaphambi kokulethwa (wonke umshini kufanele usebenze amahora angaphezu kwama-48)

Izindinganiso zobuchwepheshe

1.Ukuzihambela ngokwakho kokudayela kwenaliti yaphezulu

Okujwayelekile≤0.05cm

2.Ukuyindilinga ngokwakho kokudayela yenaliti yaphezulu

Okujwayelekile≤0.05cm

3.Ukuyindilinga ngokwakho kwesigubhu senaliti ephansi

Okujwayelekile≤0.05cm

4.Ukuzihambela ngokwakho kwesigubhu senaliti esiphansi

Okujwayelekile≤0.05cm

5.Ukuhlelwa okufanayo kokudayela kwenaliti ye-un kanye nesigubhu senaliti esiphansi

Okujwayelekile≤0.05cm

6.Ukuyindilinga okufanayo kokudayela yenaliti yaphezulu kanye nesigubhu senaliti yaphansi

Okujwayelekile≤0.05cm

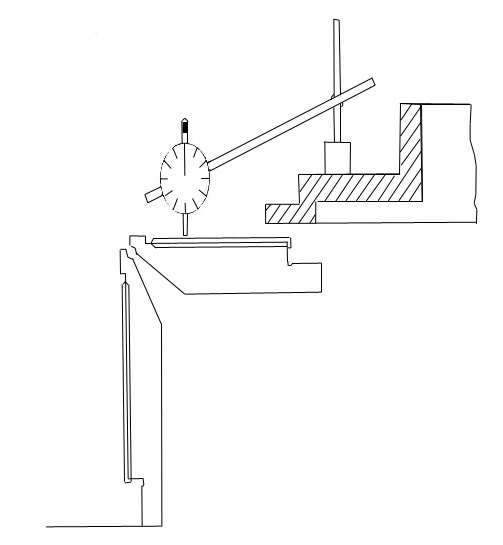

7.Isikhala phakathi kwamakhamera aphezulu nesigubhu senaliti

0.15mm-0.25mm

8.Isikhala phakathi kwama-down cams nesigubhu senaliti

0.15mm-0.25m

Ukulungiswa okuyisisekelo

Imvamisa, umshini wethu usebenzisa umjovo oqinile ngaphambi kokulethwa, kodwa ukuze ukwazi ukukuvumela ukuthi usebenzise umshini ngokuphepha okwengeziwe, hlola futhi ulungise ngaphambi kokuwusebenzisa.

1.Hlola i-motor drive

Xhuma amandla, futhi uhlole indlela yokushayela yenjini, uma isiqondiso sihlukile nelebula lemoto, shintsha izintambo zenjini ngokushesha (shintshanisa izigaba ezimbili kwezintathu zetheminali yemoto).

2.Hlola kanye nokulungiswa kwebhande le-motor drive

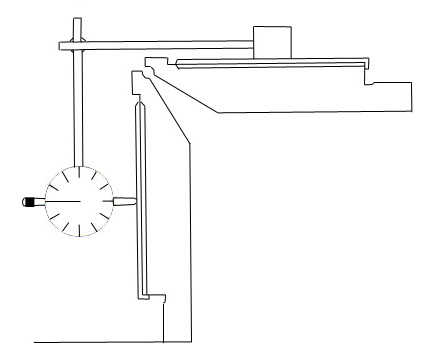

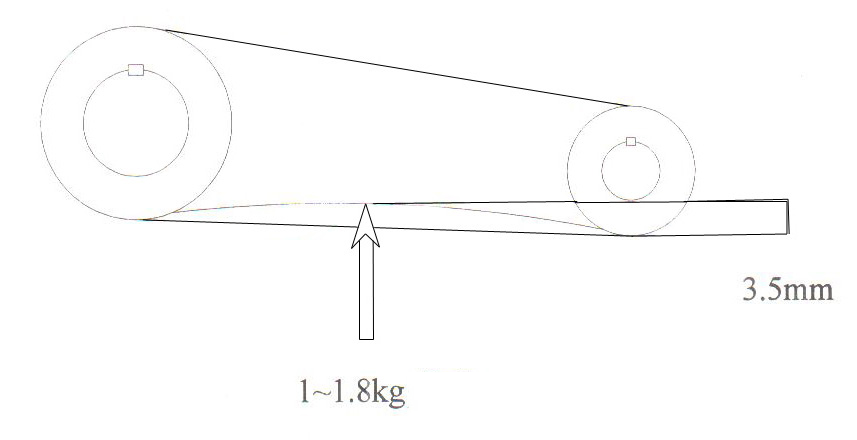

Ngaphambi komsebenzi, hlola ukungezwani kwebhande le-motor drive.Thola amandla angu-1-1.8kg phakathi nebhande, yenza ukuguqulwa komugqa webhande kube ngaphansi kuka-3.5mm, ukulungise kuze kube yilapho uhlangabezana nemfuneko.Lungisa indlela: khulula isikulufu se-motor base lock, lungisa isigqoko sikasilika esicindezelayo, kuze kube yilapho ukungezwani kuhlangabezana nemfuneko, bese uqinisa isikulufu.

Qaphela: ezinsukwini ezintathu zokuqala, phinda uhlole kanye, futhi uhlole njalo ngemva kwezinyanga ezintathu.

3.Ukulungiswa kwesistimu yokuvuthela

Ifeni yesistimu yokufutha idinga ukulungisa ngokuqondile, kuze kube yilapho ifeni itholakala endaweni engcono kakhulu.Ngakho-ke lapho amandla evuliwe, ifeni ingavuthela wonke amakhona okudla kwentambo.

4.Ukulungiswa kohlelo lokudluliswa kwentambo

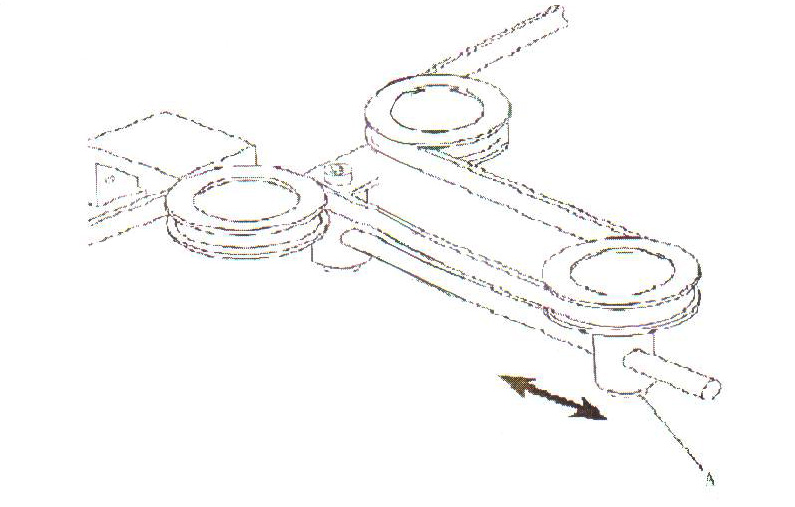

(1) Ukulungiswa okuncane kwepuleti le-aluminium eliphakela intambo.

Shintsha ububanzi bepuleti le-aluminium eliphakelayo, isilinganiso sokudlulisela sizoshintshwa, futhi inani lokuphakela intambo lizoshintshwa.Izindlela zimi kanje:

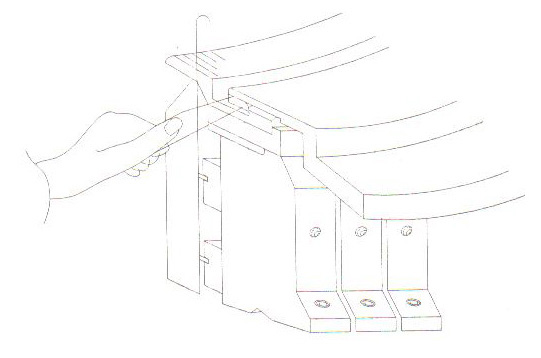

①Okokuqala, sebenzisa isikrufu ukuze ukhulule inadi elingundiyela phezulu kwepuleti le-aluminium eliphakelayo.

②Zungezisa ikhava ukuze ithi “+”, izilayidi eziyi-12 ezingaphakathi kwepuleti zizonwebeka ziye ngaphandle, ukuze kwandiswe ububanzi besondo, futhi kwandise nenani lokuphakelwa kwentambo.Ngokuphambene, zungeza ku-“-”, inani lokuphakela intambo lizokwehla.Lapho uzungezisa, hlala uhambisana, ngaphandle kwalokho, izilayidi zingase zehle ku-slot.

③ububanzi bobubanzi bepuleti le-aluminium eliphakela intambo lizoba: 70-202mm

④Ngemva kokulungisa ipuleti, phinda ukhiye inathi eliyindilinga.

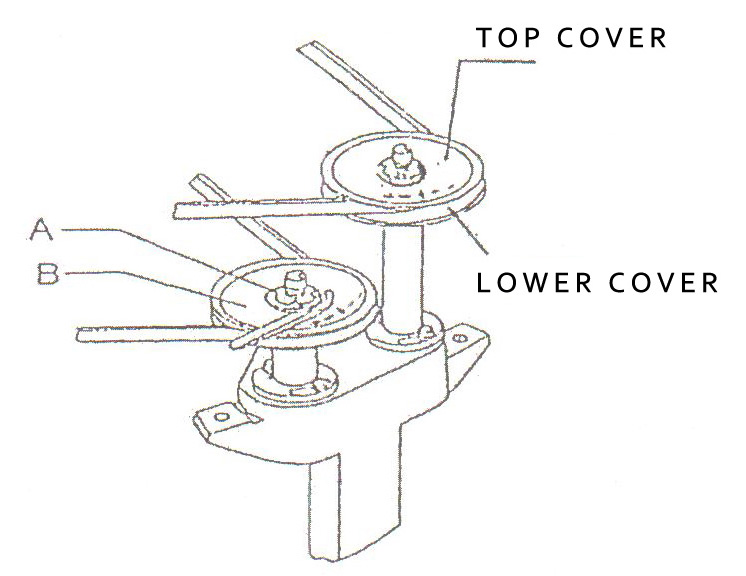

(2)Ukulungiswa kokuqina kwebhande lokudlulisa intambo

Uma ibhande lixega kakhulu, idivayisi yokugcina intambo izoshelela futhi imile, futhi izoba nomthelela ekuphakeleni kwentambo.Ngakho-ke ngaphambi kokusebenza, lungisa ukudluliswa kokuphakelwa kwentambo ngendlela engezansi:

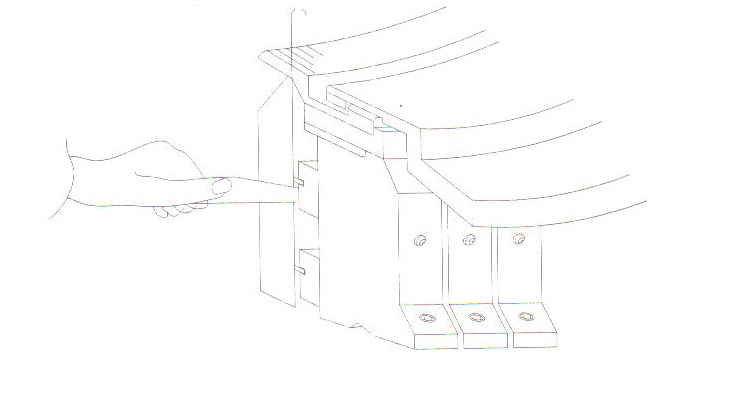

①khulula isikulufu A

②Donsa isondo lokuskrola ulikhiphele ngaphandle eduze kwesilayidi, qiniseka ukuthi ingcindezi yebhande kudivayisi yokugcina uchungechunge iyafana.

③khiya isikulufu A

1.isheke lokugcotshwa kwamafutha

Bheka ukugcotshwa kwengxenye ngayinye yesistimu yokudlulisela kanye nesistimu yokugingqa indwangu, uma kukhona okungavamile, engeza ukugcotshwa kwamafutha ngesikhathi.

Isahluko Sesine

Izinkinga Ezivamile Ngesikhathi Sokuluka

Imbobo

·Okukhulu okudalwa yintambo emagebhugebhu

·Ngenxa yezinga elibi noma intambo eyome kakhulu

·Indawo engalungile yomlomo wokuncelisa intambo

·Ukudonsa kwentambo kukhulu kakhulu noma ukungezwani okugoqiwe kukhulu kakhulu

·Ukuminyana kwamakhoyili kuphezulu kakhulu

·Indilinga yokuluka yinde kakhulu, futhi indwangu izacile kakhulu

Inalithi engekho

·Indawo engalungile yomlomo wokuncelisa intambo

·Ukuqina kwentambo kuncane kakhulu

·Indilinga yokuluka yinde kakhulu

·Imbobo yokuncelisa engalungile

·Umlomo wokuphakela izintambo ezingaphezulu uphezulu kakhulu

I-Tuck phenomenon

·Ukuqina okuhlanganisiwe kuncane kakhulu

·Ukuminyana kwendwangu kuphezulu kakhulu

Ulimi lwenaliti lulimale

Ukulimala kolimi lwenaliti

·Indawo yomlomo wokuncelisa iphakeme kakhulu, ngaphambili kakhulu noma emuva kakhulu, qaphela ukuthi intambo yangena emlonyeni wokuncelisa.

Ukushayisana kwenaliti

·Ukungabi khona kwamafutha noma ukusetshenziswa ngendlela engafanele

·Ikhwalithi yentambo iyimbobo kakhulu noma i-creel ayifaneleki igeji

·Ijubane liphezulu kakhulu noma ukuminyana kwendwangu kuphezulu kakhulu

·Kubangelwa isigubhu senaliti esiphukile, ukudayela inaliti noma ikhamera

·Ukunitha kwangempela akubushelelezi, akuhlanzeki ngokwanele

·Igebe phakathi kodayela wokunitha nesigubhu lalingalungile

Imivimbo

·Ukulungiswa okungalungile kokuqina kwentambo yangaphezulu

·Izinga lentambo lihlukile

·Ukulungiswa kwesimo esingafanele sesondo loboya obucindezelayo

·Ukulungiswa okungafanele kwentambo engaphansi

Indawo yokuphuzela utshwala

·Ummese awubukhali

·Uthuli oluningi emmese, kanti ihuku lommese liqine kakhulu

·Ukuntuleka kwamafutha, inani likawoyela lincane kakhulu

Isahluko sesihlanu

Isondlo

Ijubane eliphezulu nokunemba okuphezulu komshini wokuluka wesimanje kudinga isicelo esiphezulu sokulungiswa, ngakho-ke, inkampani yethu ifinyeze ngokungathi sína indlela ethile yokulungisa umsebenzi wansuku zonke, ngethemba ukuthi amakhasimende angakwazi ukusebenzisa iziphakamiso, ukwenza umshini usebenze usesimweni esihle kakhulu.

Ukusetshenziswa kokuqala nokugcinwa komshini

I-1.Lapho umshini usuqedile ukufakwa futhi uqala ukukhiqiza, isivinini asikwazi ukushesha kakhulu, phakathi nesonto lokuqala amahora angu-20 ngosuku), gcina isivinini ngaphakathi kwe-10r / min.ngemva kwesonto elilodwa, kancane kancane ulungise isivinini sibe esivamile

2.Inyanga yokuqala ingeyesikhathi sokusebenza, inyanga eyodwa kamuva, shintsha uwoyela womshini ku-grail yomshini, futhi ushintshe njalo ezinyangeni ezintathu.

3.Gcina uwoyela womshini ungu-1/2-2/3 weleveli kawoyela, unikeze ngesikhathi lapho uwoyela eshoda, ukugwema ukulimaza ipuleti eligugile futhi ubangele ukukhiya komshini.

Isondlo sansuku zonke

1. Hlanza uthuli olunanyathiselwe phezu kwentambo kanye nangaphezulu komshini njalo, ukugcina ingxenye yokunitha kanye nemishini yokuhlanganisa ihlanzekile.

2.Hlola idivayisi yokumisa okuzenzakalelayo kanye nedivayisi yokuphepha njalo lapho kushintshwa, uma kukhona okungavamile, ukulungisa noma ukukubuyisela ngokushesha.

3.Hlola idivayisi yokukhipha intambo njalo, uma kukhona okungavamile, yilungise ngokushesha

4.Hlola isibuko sikawoyela womshini kanye neshubhu yezinga likawoyela wethangi

Ukugcinwa kwamasonto onke

1.Hlanza ipuleti le-aluminium esheshayo, futhi uhlanze inqwaba yothuli epuletini

2.Hlola ukuthi ukushuba kwebhande kokudlulisela kujwayelekile yini, futhi ukudlulisela azinzile

3.Hlola ukujikeleza komshini wokugoqa indwangu

Isondlo sanyanga zonke

1.Susa yonke i-cambox, ukuhlanza uthuli

2.Hlanza uthuli susa ifeni futhi uhlole ukuthi isiqondiso somoya silungile yini.

3.Hlanza uthuli lwazo zonke izesekeli zikagesi

4.Buyekeza ukusebenza kwazo zonke izesekeli zikagesi okuhlanganisa isistimu yokumisa okuzenzakalelayo, isistimu ye-alamu yokuphepha, uhlelo lokuhlola)

Ukugcinwa kweSemiannual

1.Hlanza yonke inaliti yokudayela nenaliti, hlola zonke izinaliti, uma kukhona umonakalo, shintsha ngokushesha

2.Hlanza umshini wokufutha uwoyela futhi uhlole ukuthi uwoyela awuvimbeli yini

3.Hlanza futhi uhlole idivayisi yokugcina izintambo

4.Hlanza uthuli namafutha enjini kanye nesistimu yokudlulisela

5.Hlola ukuthi ukuqoqwa kwamafutha angcolile akuvimbekile yini

Isondlo sonyaka

1.Izingxenye zokuluka ziyinhliziyo yomshini wokuluka, isiqiniseko esiqondile sekhwalithi yendwangu, o, kubaluleke kakhulu ukugcina izingxenye zokuluka

2.Hlanza i-groove yenaliti, ukugwema uthuli endwangu yokuluka.indlela: buyisela intambo ngekhwalithi ephansi noma imfucumfucu ntambo, vula umshini ngesivinini esikhulu, futhi ujove inani elikhulu lamafutha nge-cylinder, Sebenza ngenkathi ufaka i-refueling, kuze kube yilapho amafutha emfucuza ephuma ngokuphelele emseleni.

3.Hlola ukuthi ayikho yini inaliti eyonakele, uma kunjalo, yishintshe ngokushesha;uma ikhwalithi yendwangu iyimbi kakhulu, kufanele icabangele ukuthi ngabe zonke ziyabuyekeza yini.

4.Hlola ukuthi igroove yesilinda ilibanga elifanayo yini (noma hlola ukuthi indawo yendwangu inemigqa), ukuthi udonga lwenaliti luqinile yini.

5.Hlola isimo sokuguga samakhamera, futhi uhlole ukuthi indawo yokufaka ilungile, nezikulufu ziqinile

6.Hlola futhi ulungise indawo yomlomo wentambo ngayinye, uma kukhona umonakalo, shintsha ngokushesha.

7.Hlola indawo yokufaka yekhamera ngayinye enciphayo, ukuze uqinisekise ukuthi ubude bendwangu ngayinye buyafana

Indlela yokugcoba, uwoyela nokugcoba

1.Indlela yokugcoba namafutha

(1)Hlola umshini wokudayela nendwangu nsuku zonke, uma amafutha engaphansi kuka-2/3, engeza amafutha.Sebenzisa amafutha omshini i-N10#-N32#.Lapho ukugcinwa kwesigamu sonyaka, uma kukhona uthuli lwamafutha, shintsha ngokushesha.

(2)Hlola igiya lesisekelo sesilinda nyanga zonke, engeza amafutha, sebenzisa i-lithium lubricating grease engu-No.3

(3)Lapho ugcina uhhafu wonyaka, hlola ibhere ngalinye lokudlulisela, engeza amafutha, sebenzisa i-lithium lubricating grease No.3.

(4)Konke ukugcotshwa kwezingxenye zokuluka kufanele kusebenzise uwoyela wokunitha (okuhlanganisa nowoyela womshini wokujova), njengamafutha omshini wokuluka oyindilinga oyindilinga wesivinini esikhulu.

2.Ukugcotshwa

Yazi kahle uhlobo lwamafutha kanye nesikhathi sokugcoba sengxenye ngayinye, ukuze uqiniseke ukuthi wonke umshini ungagcotshwa ngesikhathi esimisiwe ngamafutha asethiwe kanye nesilinganiso sokusetha.

Isikhathi sokuphumula kanye nokucatshangelwa okuvaliwe

Ukugcinwa nokunakekelwa komshini kufanele kwenziwe ngokwezinqubo zokulungisa isigamu sonyaka, qala ngokufaka uwoyela wokugcoba ezingxenyeni zokunitha, bese uhlanganisa uwoyela we-antirust enalithini yokunitha, ekugcineni umboze umshini ngothayela owawucwiliswe emafutheni yenaliti futhi wavalwa kowomile nohlanzekile. indawo.

Ukugcinwa kwezinsimbi zemishini kanye nezingxenye ezisele

Ngengxenye esetshenziswa okuvamile futhi egqokwa ngokushesha, indawo ebekiwe evamile iyisiqinisekiso esibalulekile sokuqhubeka kokukhiqiza.Indawo yokugcina impahla kufanele ibe epholile, yomile futhi ihluke kancane ekushiseni, ukuhlola okuvamile nakho kuyadingeka.

Indlela yokugcina imi kanje:

1.Ukugcinwa kwenaliti yesilinda nokudayela yenaliti

Hlanza inaliti yesilinda kuqala, bese uyifaka ebhokisini lezinkuni elalifake amafutha omshini kanye nokugoqa kwendwangu kawoyela, ukuze ugweme ukungqubuzana nokuguqulwa.Uma usebenzisa umoya ocindezelwe ukususa uwoyela womshini ngaphakathi kwenaliti yesilinda, bese wengeza uwoyela yenaliti.

2.Ukugcinwa kwamakhamera

Ukuhlukanisa amakhamera bese ubeka endaweni yokugcina, eyayinesitoreji ebhokisini bese wengeza amafutha e-antirust ukugwema ukugqwala.

3.Ukugcinwa kwenaliti yokuluka

(1) Inalithi yokuluka entsha kufanele ifakwe ebhokisini lokupakisha lokuqala, futhi ungalususi uphawu.

(2) Inaliti yokunitha endala kufanele ihlanzeke, ihlole, ikhethe okonakele, ihlukanise futhi ibekwe endaweni yokugcina namafutha yenaliti ukuze kugwenywe ukugqwala.

Ukugcinwa kwezingxenye zikagesi

1.Ukubaluleka kwesondlo

Isifunda somshini wokunitha siqukethe ingxenye ye-elekthronikhi enembile——inverter.Ekusetshenzisweni okungokoqobo, ngenxa yezinga lokushisa elizungezile, umswakama, ukudlidliza, uthuli, amagesi ezonakalisayo nezinye izici zemvelo, ukwethembeka nempilo yesevisi ye-inverter izothinteka kabi.Uma inakekelwa kahle, hhayi nje ukuqinisekisa ukwethembeka kodwa futhi nokwelula impilo yesevisi, futhi kuzonciphisa ukulahlekelwa kokukhiqiza okubangelwa ukwehluleka ngezikhathi ezithile.Ngakho-ke, ukugcinwa okuvamile kwe-inverter kanye ne-peripheral circuits kuyadingeka.

2.Hlola i-inverter nama-peripheral circuits

Ku-inverter yomsebenzi osebenzayo kanye namasekhethi okulawula, ngokuvamile kufanele enze amasheke alandelayo:

(1) Izinga lokushisa lemvelo: Okujwayelekile ngokujwayelekile - 10 ℃ ~ + 40 ℃ ububanzi, ku-25 ℃ noma kunjalo.

(2) I-voltage yokufaka ye-inverter: ububanzi obujwayelekile ngu-380V±10%.

(3) Ukuhlanza njalo impukane iye phansi, uthuli ebhokisini lokulawula ukuze kugcinwe ibhokisi likagesi lihlanzekile ngaphakathi, kuphakanyiswe ukuthi kuhlanzwe kanye ngosuku ngemva koshintsho lweshifu.

(4) Uwoyela uzosheshisa izintambo ezigugayo, uma ibhokisi likagesi ngaphakathi ngephutha lingena emafutheni, sicela uhlanze ngesikhathi.

(5)Hlola njalo isiphephetha-moya sebhokisi likagesi, uma sonakalisiwe sicela ushintshwe kusenesikhathi, ukuze uqinisekise ukuthi izinga lokushisa langaphakathi lebhokisi likagesi aliphezulu kakhulu.

3.Ukuhlola okuvamile

Ukusebenzisa isikhathi sonyaka sokulungisa imishini, futhi ubeke ukugxila ekuhloleni ku-inverter yangaphakathi bit.

(1)Lapho kulungiswa njalo, kumele kunqamule ugesi ngaphambi kokusebenza kuze kucishwe inkomba yamandla ebhasi ye-DC ye-inverter, ngokuvamile okungaphezu komzuzu owodwa (umthamo omkhulu we-inverter, isikhathi eside sokulinda), bese siqhuba. ukuhlinzwa.

(2) Hlukanisa ikhava yangaphandle ye-inverter, uvale ibhodi lesifunda se-inverter kanye namamojula angaphakathi e-IGBT, amatheminali okokufaka nokukhiphayo nezinye izingxenye.Sebenzisa indwangu kakotini enama-agent okuhlanza akhethekile ukuze usule izindawo ezingcolile ebhodini lesekethe.

(3)Hlola ukugqunywa kwentambo yomthofu yangaphakathi ye-inverter ukuthi inokugqwala noma imikhondo ephukile, uma isitholakele kufanele ilashwe noma ishintshwe ngokushesha.

(4)Ngenxa yokudlidliza, ukushintsha kwezinga lokushisa neminye imiphumela, amanye amayunithi okubamba e-inverter afana nesikulufu ahlala eguquguquka, kufanele aqinise sonke isikulufu futhi.

(5)Hlola futhi uthole ukuthi ingabe okokufaka nokukhiphayo, ama-transformer, njll. ayashisa ngokweqile, ayavuza, angenasici, ashintsha umbala futhi ashile noma anephunga.

(6)Hlola ukuthi umthamo ophakathi nendawo we-DC yokuhlunga i-electrolytic capacitor nokusebenza kokushaja kuhle, noma ngabe ukubukeka kunokuqhekeka, ukuvuza, ukuvuvukala, njll., impilo yesevisi ye-filter capacitor iminyaka emi-5, isikhathi eside sokuhlolwa unyaka owodwa. , futhi ngemva kweminyaka emihlanu ngicela uyishintshe.

(7)Hlola ukuthi ingabe ukusebenza kwefeni okupholisa kusesimeni esihle yini, uma uthola umsindo ongajwayelekile, ukudlidliza okungavamile kufanele kushintshwe ngokushesha.Uma kungenjalo i-inverter izoshisa kakhulu, futhi isebenze impilo yokusebenza ye-inverter.Umjikelezo wokushintsha abalandeli ngokuvamile uyiminyaka engu-2-3.

(8)Hlola ukumelana nokushisa kwe-inverter ukuthi isendaweni evamile yini (Zonke amatheminali kanye netheminali yomhlaba), Qaphela ukuthi awukwazi ukusebenzisa i-megameter ukukala ibhodi lesekhethi, ngaphandle kwalokho izolimaza izingxenye ze-electronic zebhodi lesekethe.

(9)Nqamula ikhebula le-R, S, T elishintshashintshayo elinesiphetho samandla, nqamula ikhebula le-U, V, W elinesiphetho se-motor, linganisa ukufakwa phakathi kwe-conductor yesigaba ngasinye sekhebula nokuvikela indawo ephansi nge-megameter ukuthi ukuhlangabezana nezidingo, ngokwejwayelekile kufanele kube kukhulu kuno-1MΩ.

(10)Ngaphambi kokufaka isiguquli esisebenza lapho ukulungiswa kuqediwe, isiguquli kufanele singenzi lutho ngemoto bese sivivinya imizuzu embalwa, siqinisekise ukujikeleza kwemoto.

Isikhathi sokuthumela: Apr-20-2022